Precision CNC Multi-Axis Milling Capabilities

Match your part to the right mill & mitigate risk through a higher caliber of quality assurance

Milled Components, Subassemblies, & Turnkey Solutions for Critical Industries

When precision and quality are paramount for your complex products, you need a manufacturer who can serve as a trusted partner for all of your CNC milling needs, as well as related services like subassemblies and other specialized capabilities.

Senga Engineering is your best choice for consistent, reliable, and precise CNC milling. Our facility offers more than 40 cutting-edge CNC lathes and mills, all of which offer stored setups for repeatability and time savings.

Most mills are palletized for automated long runs, and every production is supported by on-the-floor coordinate measuring machine (CMM) inspections. Senga’s unmatched quality enables “dock-to-stock” deliveries by reducing handling time.

Make it right the first time with precision CNC milling and quality assurance from Senga.

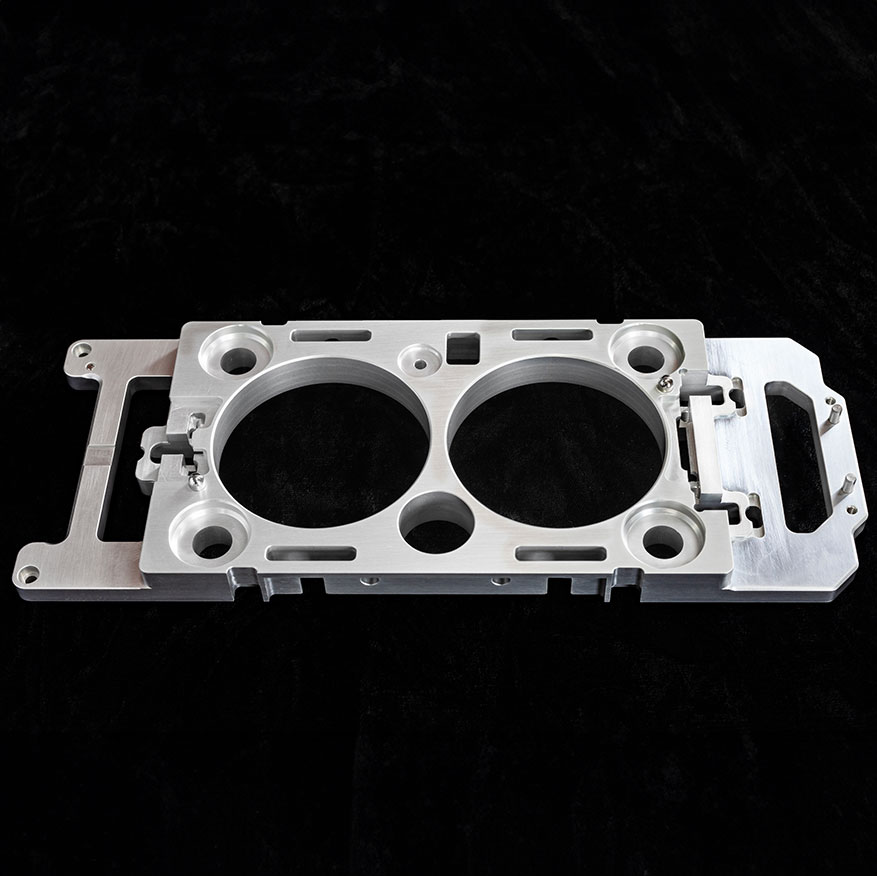

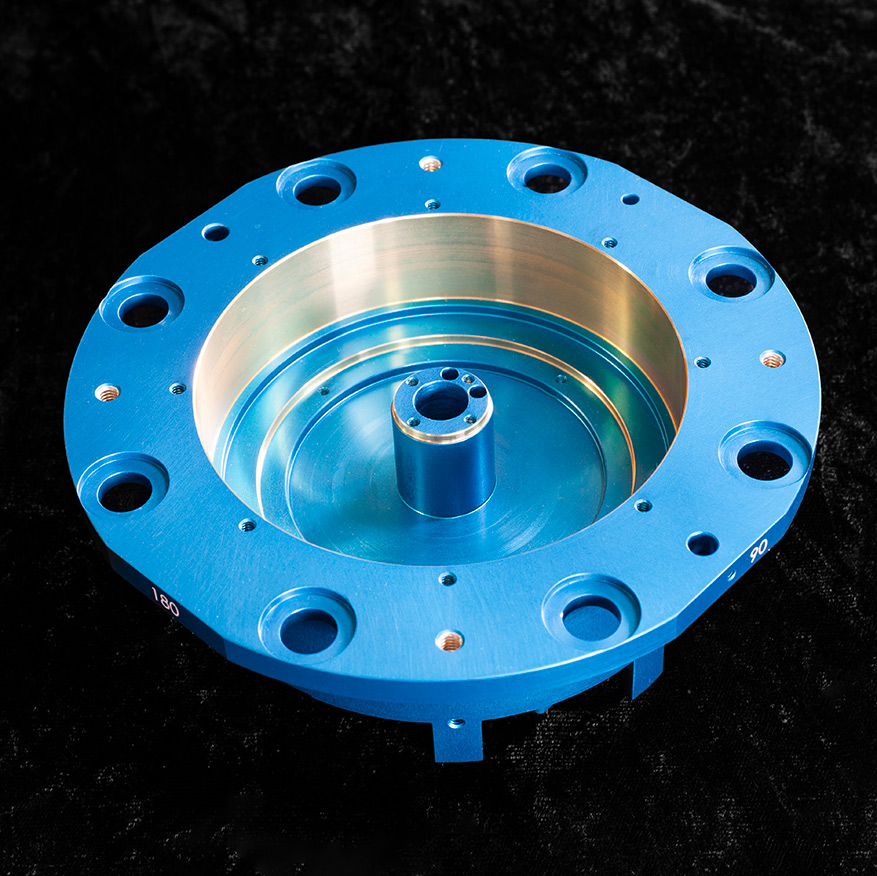

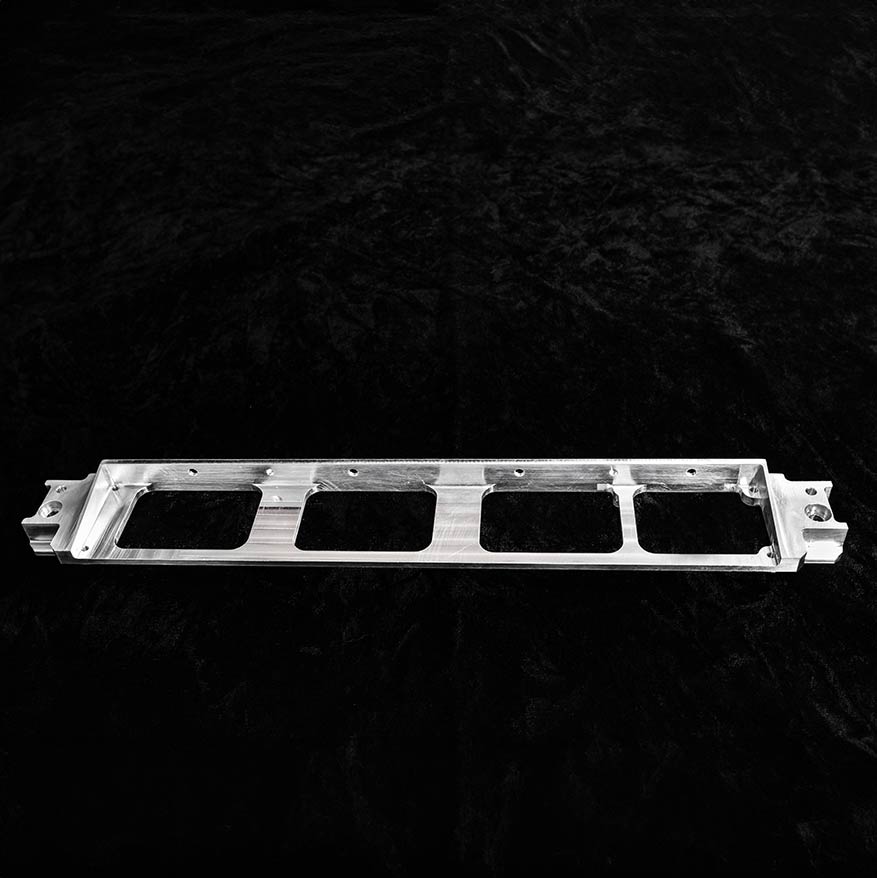

Horizontal milling offers the highest levels of speed, precision, and accuracy to ensure part conformity to print.

This form of high-efficiency continuous machining and mass production manufacturing is essential for critical industries like Medical Devices, Aerospace, Energy, and Space.

Senga’s 5-axis and 5-sided machining produces quality parts and complex work pieces in just one setting for any mechanical field.

These state-of-the-art features dramatically improve transmission efficiency and offer high-speed feeds.

Proven track record of exceptional quality

“Senga delivers high quality complex parts that go from our dock to our production floor with only very minimal inspection required, because Senga has an excellent in-house quality assurance system and proven track record of exceptional quality, thus eliminating the time and cost of incoming receiving inspection on our end.”

President, Major Alternative Energy Industry Manufacturer

Professionalism & turnaround time have been exceptional

“I feel privileged to have Senga Engineering with their capacity and capabilities. Their professionalism and turnaround time have been exceptional, not to mention the excellent care & dedication that Mike Irion shows every day. Always willing to go the extra mile to get us what we need.”

Business Operations Manager, Fiber Optic Interconnect Solutions Provider

Industries & Applications

Industrial

Full-service machine-to-print from billet, castings & forging metal additive parts