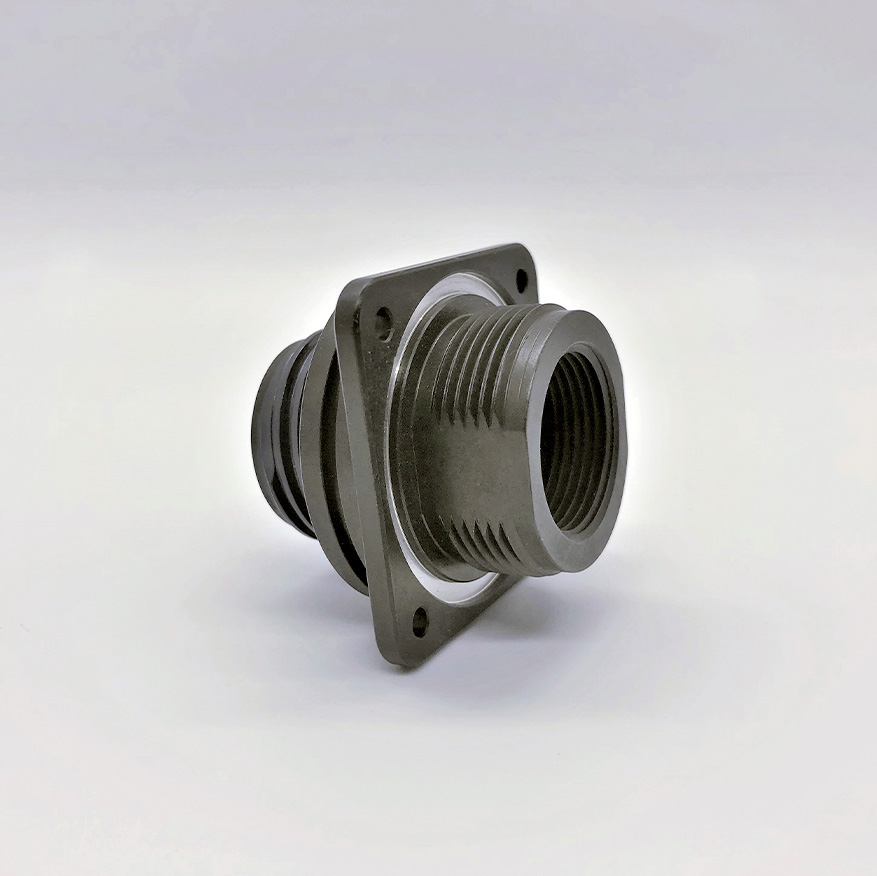

Precision CNC Multi-Axis Turning Capabilities

Dedicated to delivering higher quality precision components & improved turnaround times

Bar-Fed Material to Finished Part in One Operation for Less Handling, Faster Throughput & Higher Precision

Finding a manufacturer capable of delivering precision parts through CNC turning can be a daunting task.

You need a preferred partner who will produce consistently accurate complex components, overcome quality and delivery challenges, mitigate risk, and provide turnkey solutions as needed.

Senga Engineering offers an industry-leading combination of institutional knowledge, state-of-the-art equipment, and quality assurance that consistently meets the highest standards for demanding applications and critical industries.

Make it right the first time with precision CNC turning and quality assurance from Senga.

Okuma’s 7-axis high-speed LT lathes feature left and right spindles with upper and lower turrets for complete production on a single machine.

- Upper and lower turrets can be combined with either spindle, balancing primary and secondary operations and maximizing productivity in a small footprint

- Both turrets have live-tooling capability to incorporate mill operations

- Two equal-capacity spindles and turrets deliver full 9-axis power

- The LT simultaneously turns both ID & OD surfaces

- It features a Space Saver 2002 bar feeder with a bar capacity up to 2" in diameter

This multi-function technology also offers live tooling for light milling capability, and is well-suited for long production runs.

Okuma’s 3- and 4-axis LB and LU lathes are robust machines capable of fast setups for simple parts with shorter runs.

- Features a high power, high torque PREX motor

- Operator-friendly, open-architecture THINC®-OSP control makes integrating with peripheral equipment easy

- Allows for a wide variety of bed lengths, bore sizes and options, including live tooling, sub-spindle and Y-axis

- True 4-axis machining reduces cycle times by 30–40%

These lathes are also capable of live tooling for light milling at simple angles. And like all of Senga’s precision CNC tools, these lathes can be configured to meet the most demanding requirements for accuracy without sacrificing quality or delaying turnaround times.

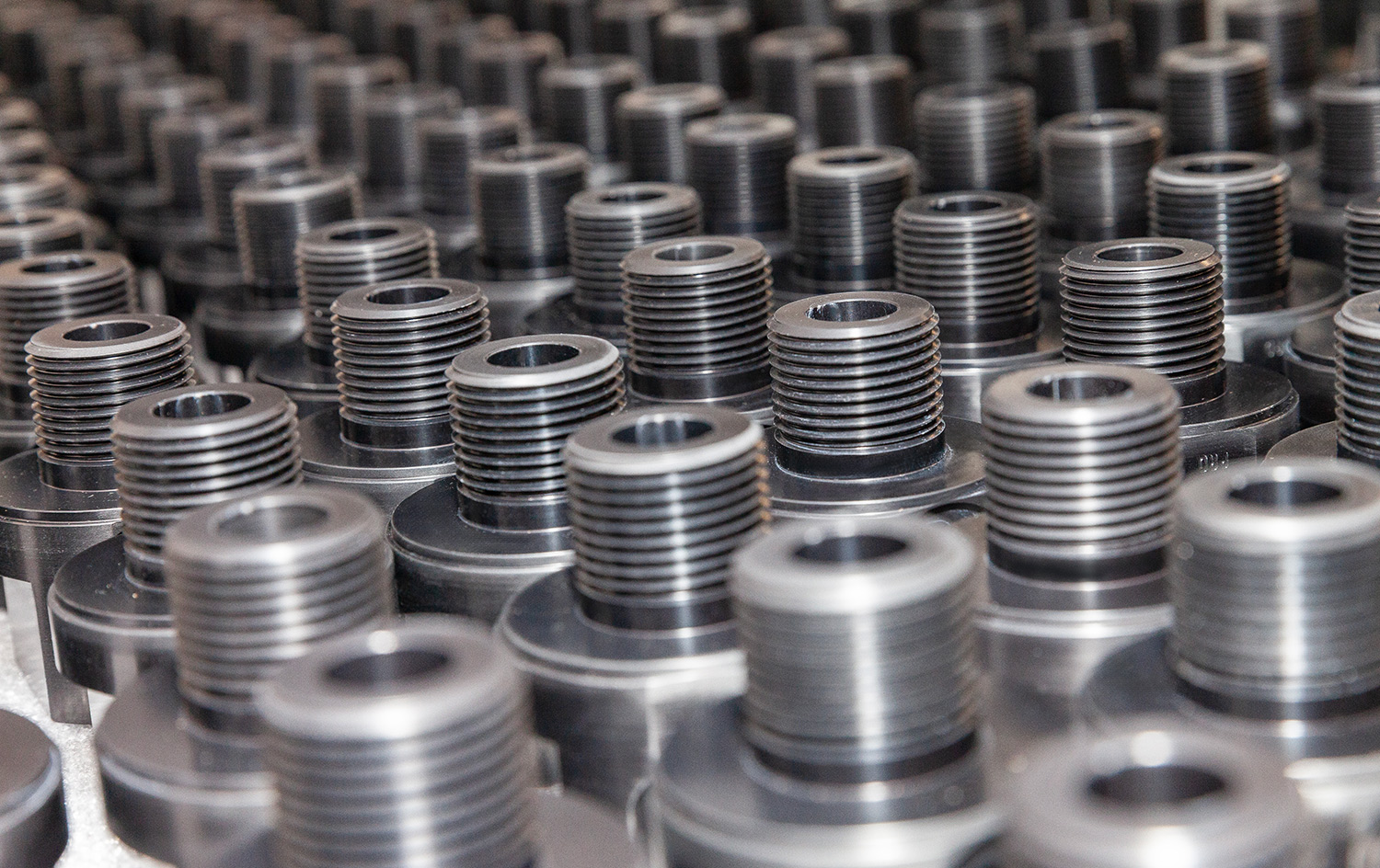

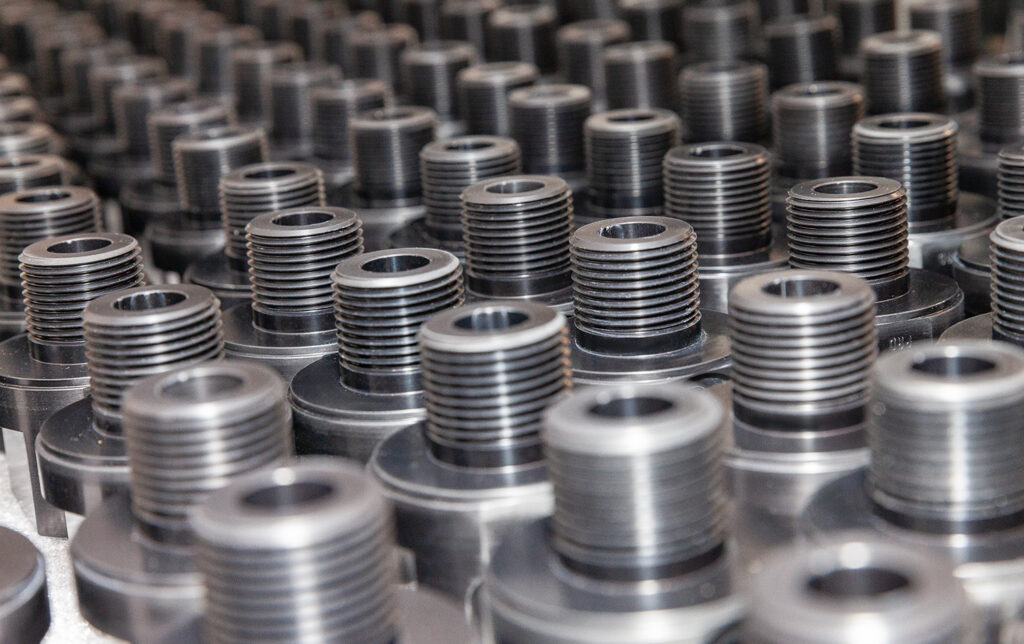

CNC Turning Products by Senga

Proven track record of exceptional quality

“Senga delivers high quality complex parts that go from our dock to our production floor with only very minimal inspection required, because Senga has an excellent in-house quality assurance system and proven track record of exceptional quality, thus eliminating the time and cost of incoming receiving inspection on our end.”

President, Major Alternative Energy Industry Manufacturer

Professionalism & turnaround time have been exceptional

“I feel privileged to have Senga Engineering with their capacity and capabilities. Their professionalism and turnaround time have been exceptional, not to mention the excellent care & dedication that Mike Irion shows every day. Always willing to go the extra mile to get us what we need.”

Business Operations Manager, Fiber Optic Interconnect Solutions Provider

Industries & Applications

Industrial

Full-service machine-to-print from billet, castings & forging metal additive parts