Value-Added Services for Precision CNC Machining Solutions

Comprehensive capabilities that add value to your components at every stage of production

Maximize Value & Minimize Handling With Unique Services & Finished Assemblies

Sending your precision CNC components through outside processes like machining, plating, and marking doesn’t just increase your time and effort unnecessarily – it also increases the likelihood of inaccuracies, delayed deliveries, and other challenges.

You shouldn’t have to create multiple purchase orders for specific stages of production. More importantly, you shouldn’t have to cross your fingers and hope that everything will turn out fine when you get a finished part that has been handled by multiple vendors.

Senga Engineering is your solution to scattered purchase orders and multi-part production runs. When you partner with us, you’re linked to all of the approved providers in our supply chain, which includes reliable guidance and responsive support at every stage. You’ll only need one purchase order – we’ll handle the rest.

Make it right the first time with precision CNC machining, value-added services, and quality assurance from Senga.

Take your designs from the concept and prototype stages into mass production with Senga Engineering’s team of mechanical, manufacturing, and quality engineers. Our engineering services include:

- Prototyping with 3D Printing or Machining (as needed)

- Design for manufacturability

- GD&T/Industrial design assistance

When you collaborate with our engineers, you’re adding decades of practical knowledge to your development team.

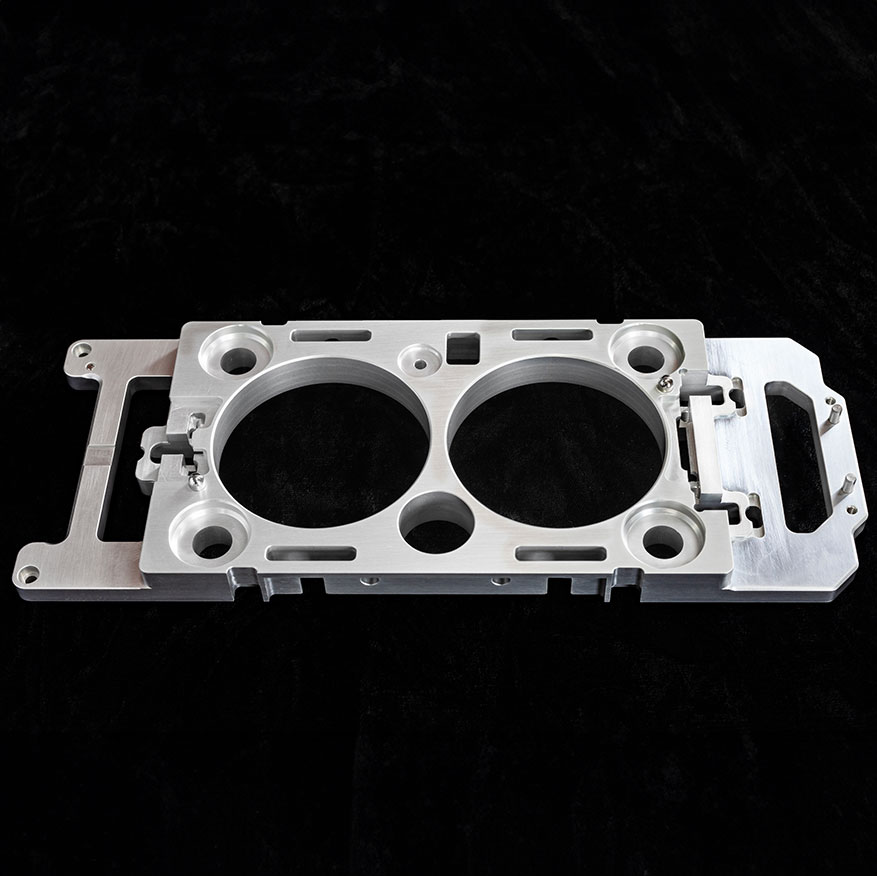

Turn your components into kitted assemblies with a variety of on-site Senga services. Our teams regularly combine as many as 20 individual parts into one SKU, and specific enhancements can include:

- Marking

- Assembly

- Serialization and lot traceability

- Helicoils

- Bag and tag

- Much more

Our team will review your requirements; if a project scope exceeds our on-site capabilities, we will investigate accommodating your needs through our Approved Supplier base.

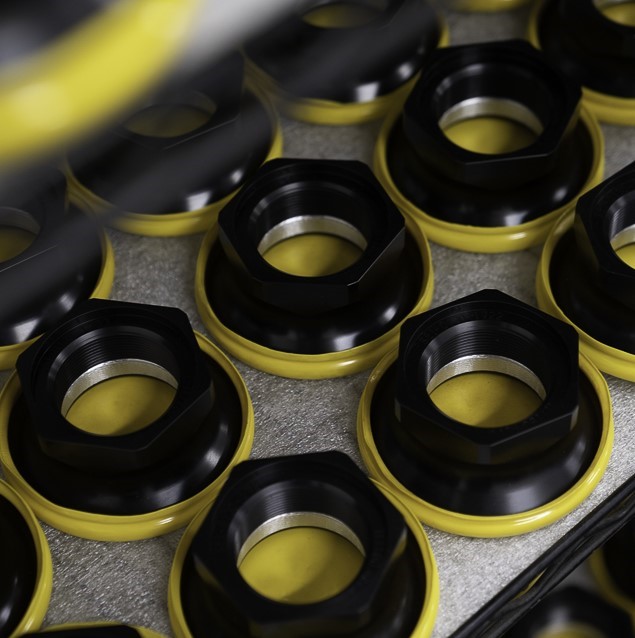

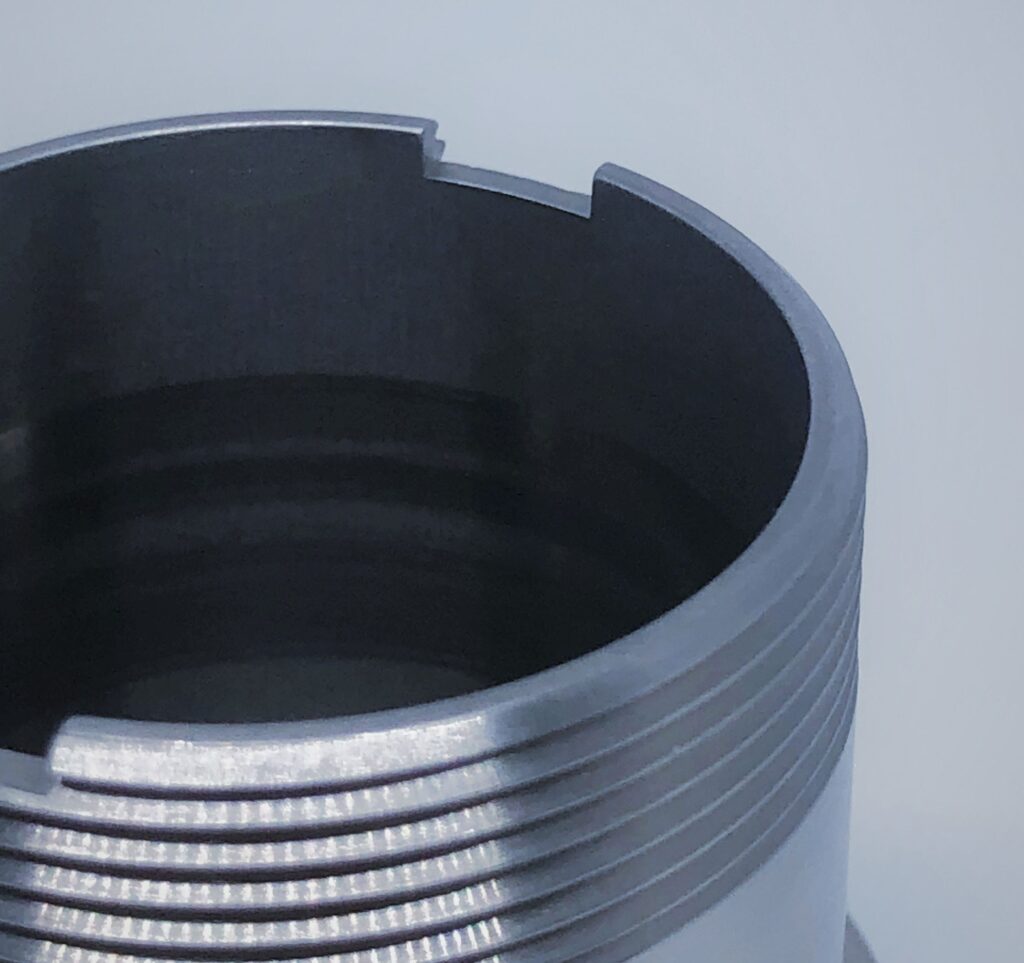

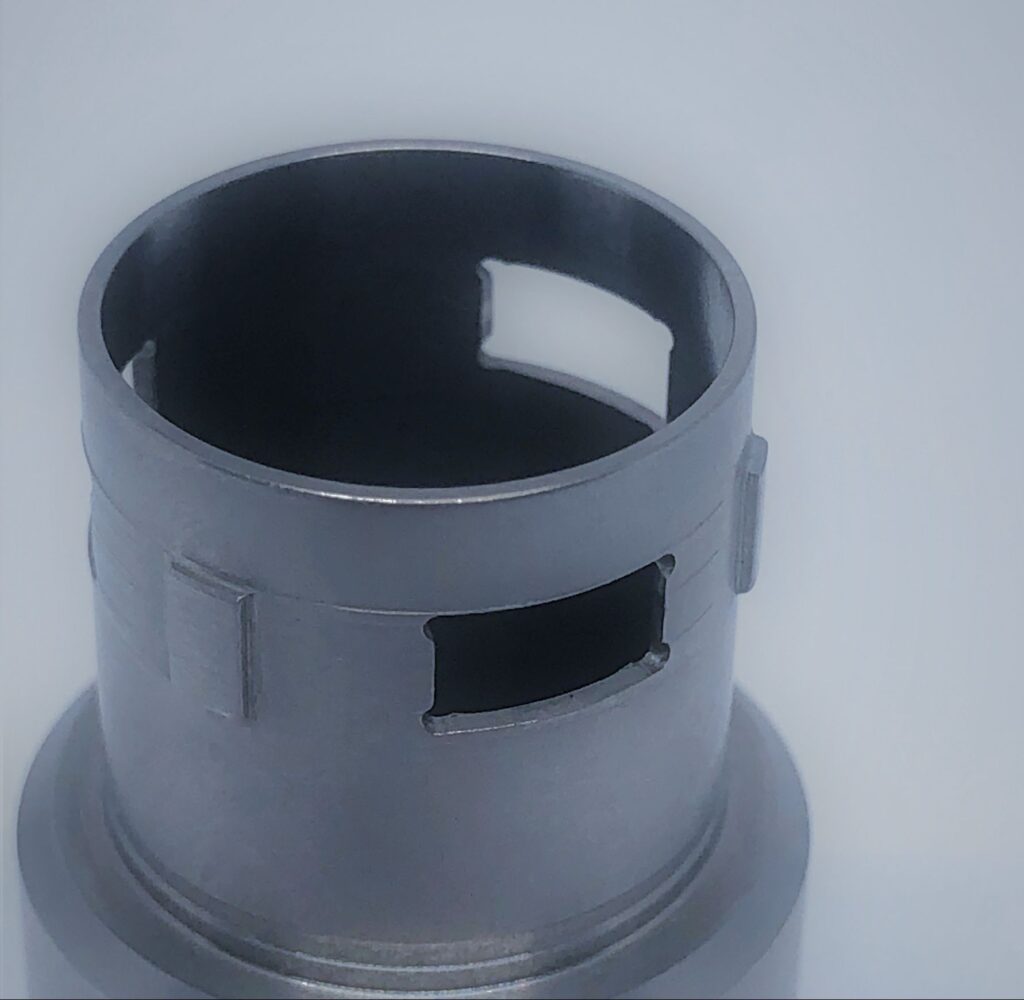

Senga uses the state-of-the-art processes and technology to optimize finishing operations that include:

- Anodizing

- Tiodizing

- Painting

- Powder Coating

- Chem Film

- Passivate

- Polishing

- Grinding

Nondestructive liquid penetrant inspection (LPI) can be performed in conjunction with these finishes.

Proven track record of exceptional quality

“Senga delivers high quality complex parts that go from our dock to our production floor with only very minimal inspection required, because Senga has an excellent in-house quality assurance system and proven track record of exceptional quality, thus eliminating the time and cost of incoming receiving inspection on our end.”

President, Major Alternative Energy Industry Manufacturer

Professionalism & turnaround time have been exceptional

“I feel privileged to have Senga Engineering with their capacity and capabilities. Their professionalism and turnaround time have been exceptional, not to mention the excellent care & dedication that Mike Irion shows every day. Always willing to go the extra mile to get us what we need.”

Business Operations Manager, Fiber Optic Interconnect Solutions Provider

Industries & Applications

Industrial

Full-service machine-to-print from billet, castings & forging metal additive parts