Industrial

Precision CNC machine-to-print components, subassemblies, & turnkey solutions for demanding environments

Full-Service Precision CNC Manufacturing For Industrial Applications

When you’re responsible for sourcing complex CNC-manufactured industrial components, your source for precision parts must be reliable, consistent, and accurate if your project is going to be successful.

Further, if you’re growing or facing urgent production needs, your precision machining partner must have the capacity to maintain quality assurance and get onboarded quickly to adhere to project timelines.

You’ll find the partner you need in Senga Engineering.

We combine decades of specialized expertise and the latest precision CNC machining technology to produce components for:

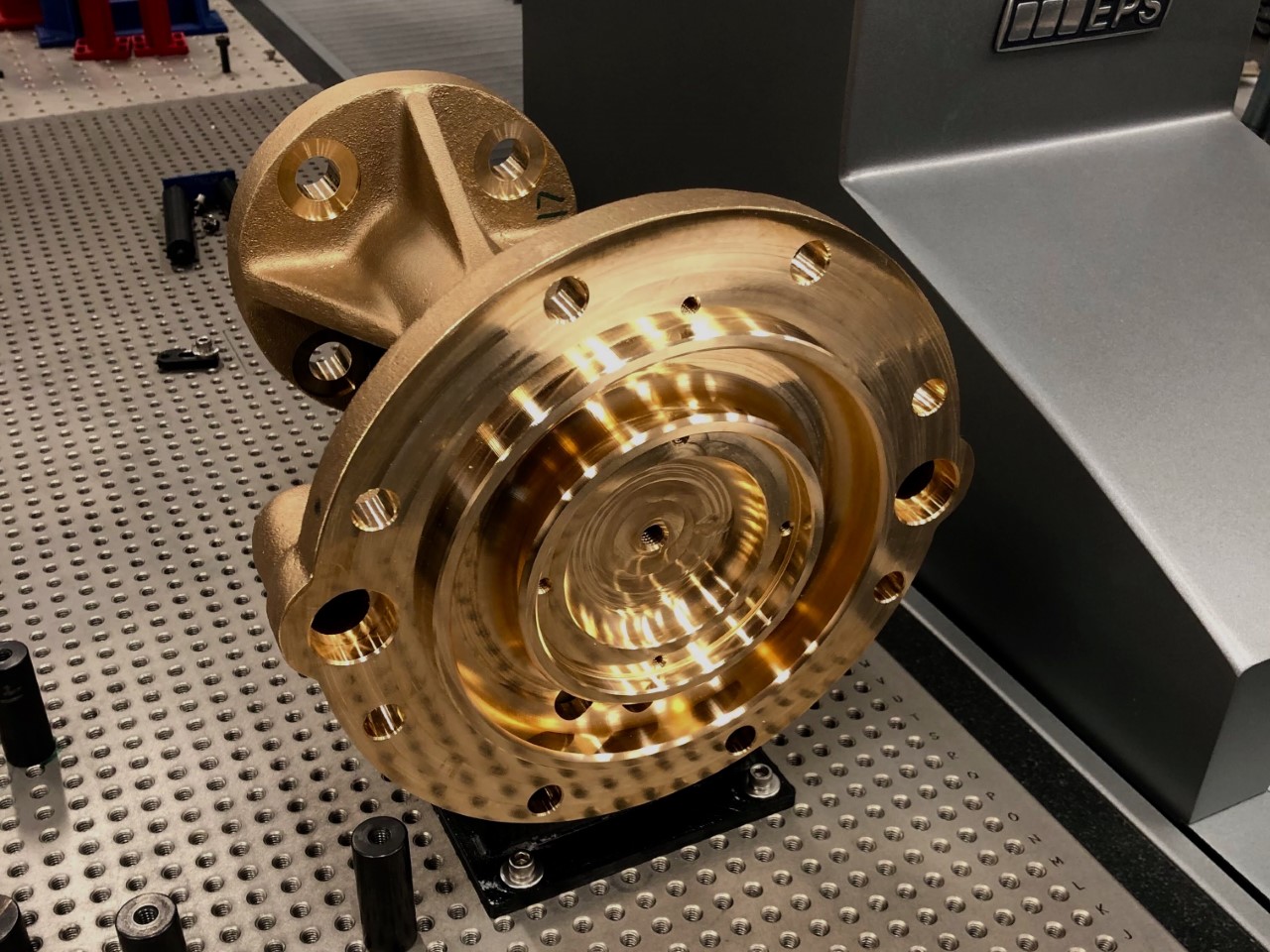

- High-pressure valves

- Hermetically-sealed connectors

- Dynamically balanced high-RPM impellers

- Cryogenic pumps

- Housings

- Fixtures

- Manifolds

- Many others

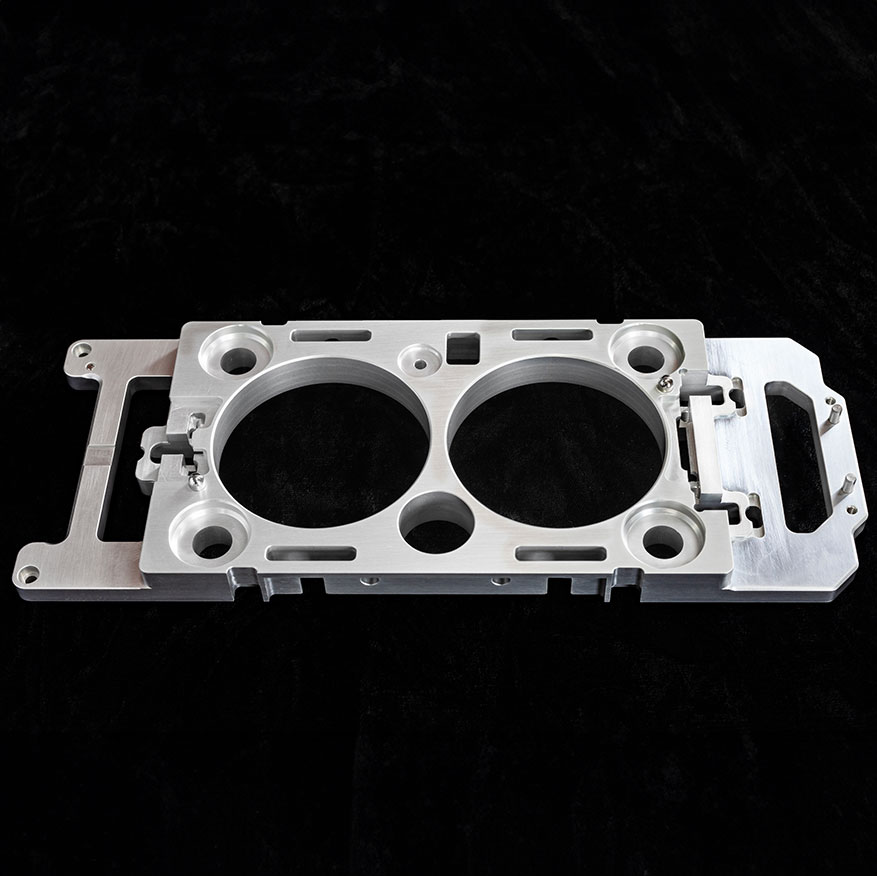

We machine-to-print many parts from billet, castings, and forgings for extremely harsh environments. Senga’s innovative systems like multitask machining reduce handling and turnaround times, ensuring accuracy and precision in components ranging from miniscule to 80 pounds pre-machined.

Our team also offers value-added services and turnkey solutions through our certified and trusted supply chain.

Full Accountability & Traceability From Dock to Stock

- Proven quality creates significant savings by eliminating the need for receiving inspections

- Serialization and robust documentation provide detailed lot traceability

- We are ITAR-controlled, ISO:9001, AS9100:D, and federally licensed for firearms components production

- Since our inception in 1979, we have been veteran-owned and privately held

The Senga Difference

CNC Machining Capabilities

40+ state-of-the-art CNC machine tools for minimal handling and unmatched quality.

Multitask Machining

Get the highest accuracy for complex applications with lathe, vertical, or horizontal machining centers and material handling operations in one setup.

Multi-Axis CNC Turning

Ensure precision with two dozen Okuma lathes capable of .25- to 12.0-inch diameters. Single-operation finishing from bar-fed material also reduces handling.

Multi-Axis CNC Milling

Choose high-efficiency continuous production from 3- to 11-axis CNC milling and turning machines that ensure accuracy for the most complex components.

Turnkey Manufacturing Solutions

Automation

Uplevel your parts with finishing, marking, heating, assembly, pre-production engineering services, and more through Senga’s supply chain.

Additive Manufacturing (3D Printing)

Increase productivity and profitability with rapid prototyping to full-scale production runs using premium materials to reduce costs and lead times.

Swiss Turning Support

Secure the smallest precision components with the tightest tolerances machined from the best materials for the most essential applications.

Frequently Asked Questions

What are Senga’s capabilities and areas of expertise?

How fast can I expect a quote?

What is your typical lead time?

Can you help with part design or suggest cost savings measures?

Yes–if you partner with Senga we can offer Design for Manufacturability (DFM) suggestions from a machining standpoint to help your engineers design a component that will be as cost effective as possible during production. We welcome the opportunity to work with your engineers early in the design phase for new product introductions.

Design for Manufacturability eBook

Find out exactly how to create designs that are practical and optimized for the manufacturing process