Make Your Parts Whole with Turnkey Solutions & Precision Machining

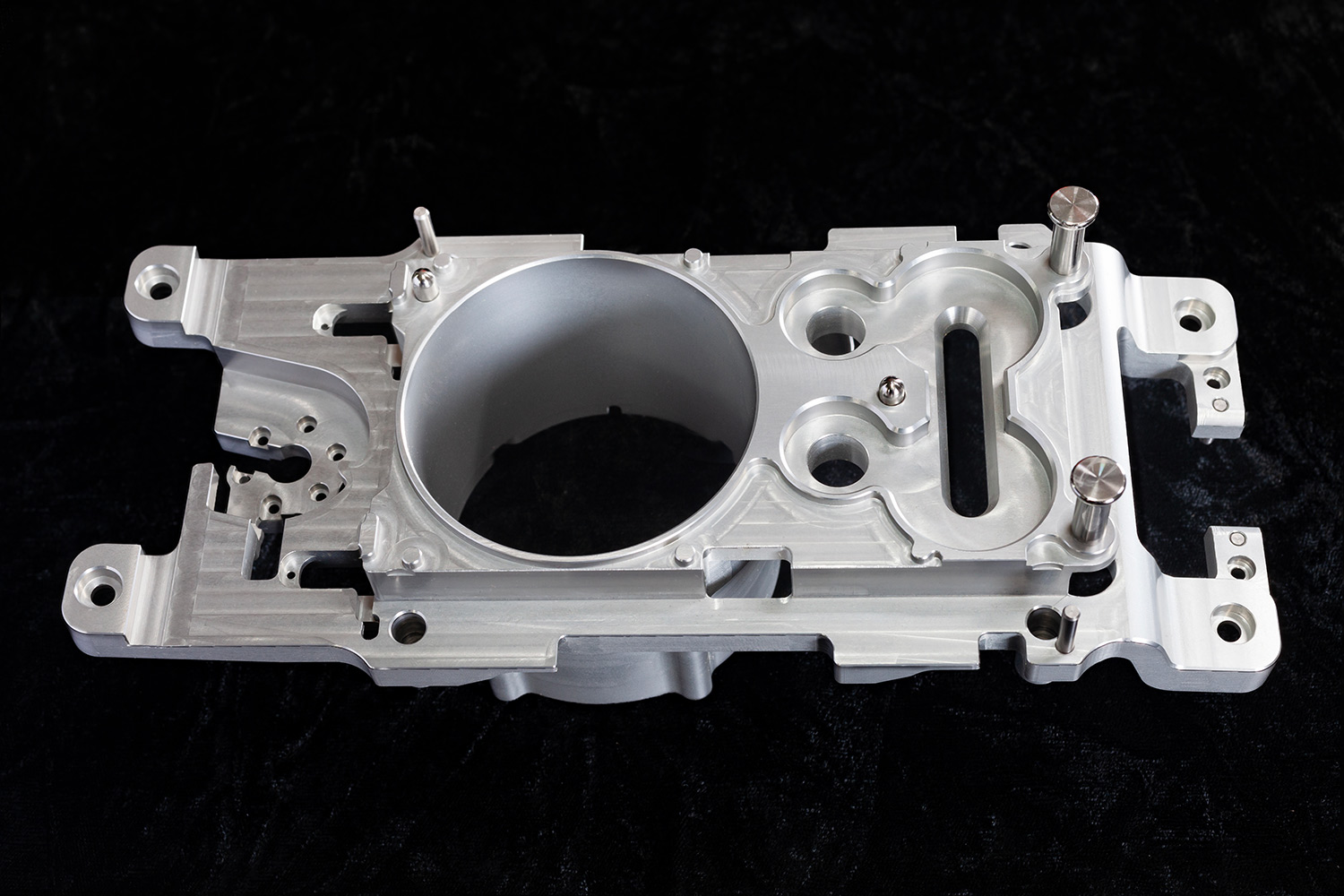

Receive kitted parts & completed sub-assemblies to minimize handling & eliminate unnecessary operations.

Comprehensive Component Creation For Frustration-Free Fulfillment

Finding the right precision CNC machining partner for your components, subassemblies, or turnkey solutions can be frustrating – especially if you have been let down by another company’s missed deadlines, inferior quality, or poor communication.

Engineers and organizations in demanding industries need a partner focused on risk mitigation who can complete components or modules, help with production obstacles, and consistently meet timelines.

Senga Engineering is your best choice for comprehensive Turnkey Manufacturing Solutions.

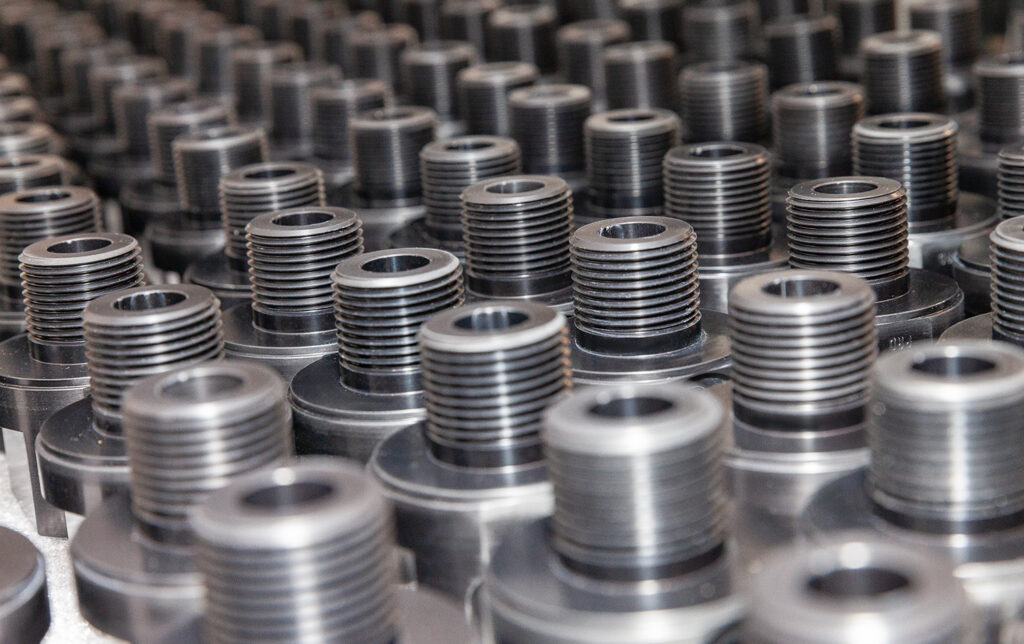

We combine decades of industry knowledge and experience with the latest innovations in CNC technologies, including over 40 state-of-the-art machines, to deliver dock-to-stock products, units, and kits. The Senga team is certified and has proven capabilities to meet industry requirements for defense, aerospace, energy, medical device, and more.

Make it right the first time with turnkey solutions and quality assurance from Senga.

Delivering precision CNC machined components at volume requires a total commitment to quality that starts with the initial design review. Senga’s dock-to-stock commitment includes:

- Careful reviews of project specifications

- Exhaustive inspections of first article components

- Multiple on-the-shop-floor CMM inspections

- Robust documentation through a registered Quality Management System

As an industry leader in CNC machining and turnkey solutions for critical industries like Aerospace, Military/Defense, and Alternative Energy, Senga maintains multiple certifications that include:

- ITAR registered and controlled

- AS9100 Rev. D certified

- ISO 9901:2015 certified

- Federal Firearms License (FFL)

Senga maintains a 14% capital reinvestment strategy to continually improve equipment and systems for modern requirements. Recent enhancements have included:

- Multitask machining for creating complex components from one stored setup

- Multi-axis milling for palletized parts with fewer defects and reduced handling

- Horizontal milling, palletizing, and stored setups for seamless production and fulfillment

- Robots for CNC machine loading & unloading, part washing, and part engraving

Turnkey Solutions by Senga

See What Success with Senga Looks Like

Hear From Our Partners

Proven track record of exceptional quality

“Senga delivers high quality complex parts that go from our dock to our production floor with only very minimal inspection required, because Senga has an excellent in-house quality assurance system and proven track record of exceptional quality, thus eliminating the time and cost of incoming receiving inspection on our end.”

President, Major Alternative Energy Industry Manufacturer

Professionalism & turnaround time have been exceptional

“I feel privileged to have Senga Engineering with their capacity and capabilities. Their professionalism and turnaround time have been exceptional, not to mention the excellent care & dedication that Mike Irion shows every day. Always willing to go the extra mile to get us what we need.”

Business Operations Manager, Fiber Optic Interconnect Solutions Provider