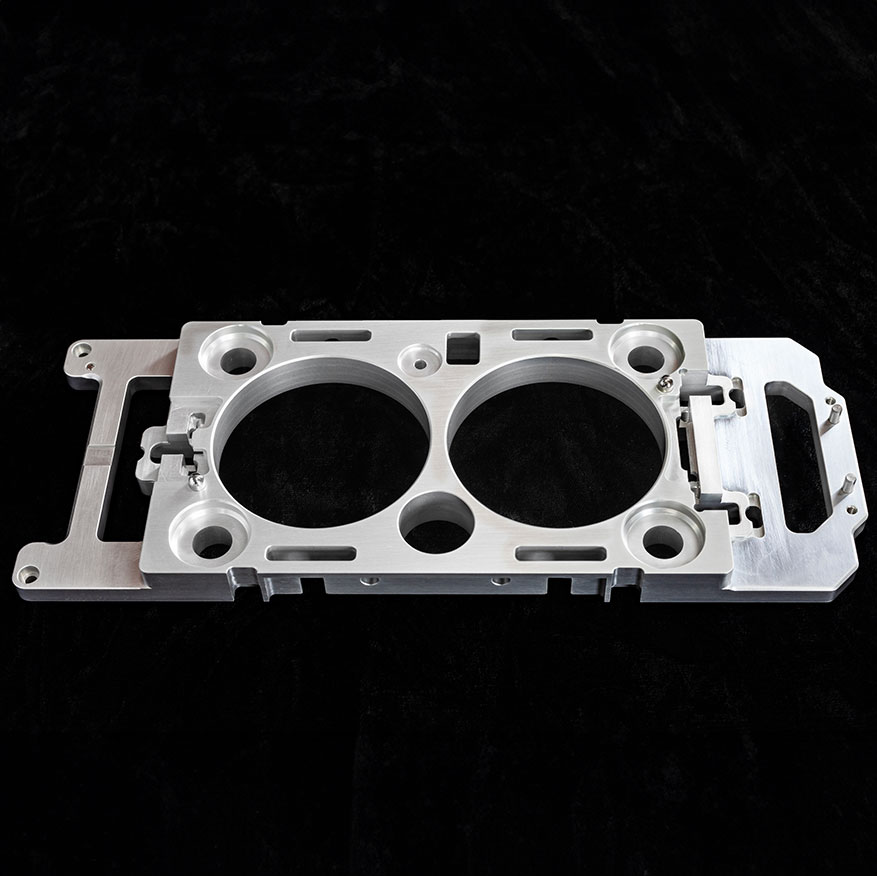

Precision Multitask CNC Machining Capabilities

State-of-the-art tools for machining complex components in one setup

Setting The Industry Standard for Consistency, Accuracy & Precision

If you’re developing a new CNC precision part for production or trying to fulfill surging orders for clients, you need a partner who will grasp what you need and guide the production of your parts through a successful run.

Clients who need multi-axis, multi-featured precision parts that meet their timeline and budget choose Senga for reliable production runs from cutting-edge tools.

Senga Engineering is committed to providing the highest quality precision CNC components, which is why multitask machining has become a big part of what we do.

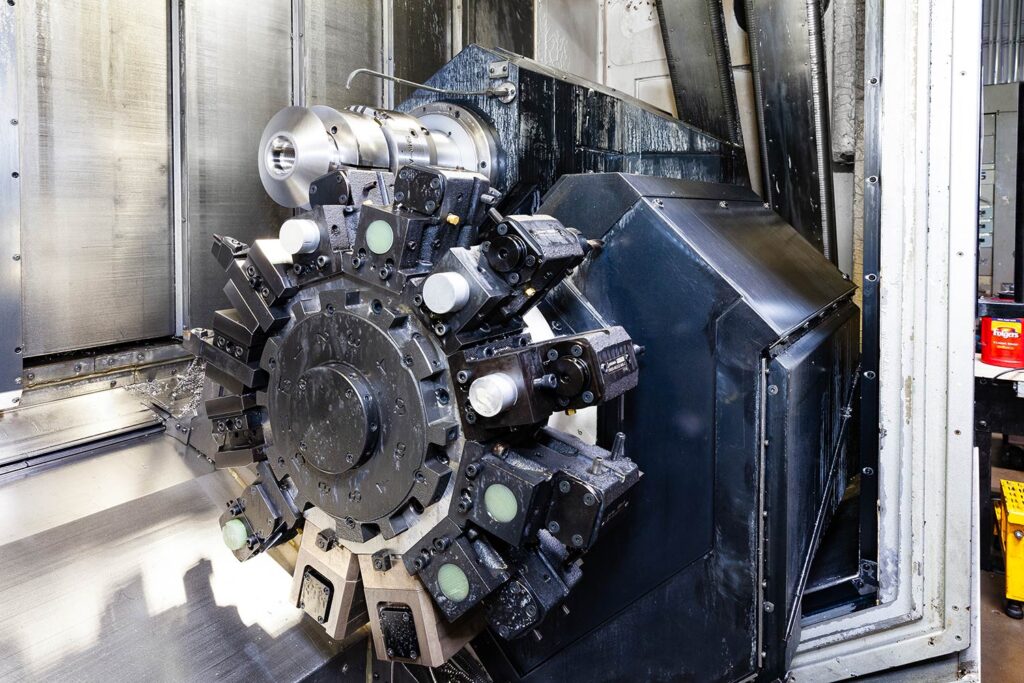

We are constantly upgrading and investing in new equipment, including multitask machining solutions like the Okuma Multus U3000, DMG NTX1000, and DN SMX2100. Senga also leverages automation for continuous and efficient 24/5 production.

Make it right the first time with precision multitask CNC machining and quality assurance from Senga.

Nine-axis machining combines 4-axis turning with full 5-axis milling to machine complex shapes in a single setup. This type of machining yields:

- Greater machining productivity compared to performing the job in a series of set ups

- Significantly reduced the time and cost of preparing multiple fixtures

- The ability to create extremely complex parts from a solid bar stock that would otherwise have to be cast or forged

- Higher precision due to one setup and zero hand-offs

Using a 9-axis machine can drastically shorten a part’s lead time to market, especially in comparison to casting the part’s general shape and then post-machining critical features.

Multitask machining allows for high production manufacturing of complicated machine parts on one machine. Benefits include:

- Material handling operations and lathe, vertical, or horizontal machining centers consolidated into one setup

- Constant, smooth flow of raw materials at all phases of production, eliminating process bottlenecks and minimizing inventory

- Automated tool carousels for partially stored setups to save time and money on repeat jobs

Multitask machines assure high accuracy for even the most complex applications.

Another great benefit of multitask machining is the time savings from drilling and milling multiple holes and slots.

- Each angled hole can be set up on a different fixture to accommodate all the hole angles

- Drilling a series of holes with different compounding angles is extremely time-consuming on a normal 3-axis set up, but Senga’s machine turrets can drill or mill at any compounding angles within its B-axis limit

While less complicated than the difficulty of machining a complex cavity or organic shape, multitask milling operations that can be completed quickly and accurately are extremely valuable for meeting project deadlines and maintaining quality.

Proven track record of exceptional quality

“Senga delivers high quality complex parts that go from our dock to our production floor with only very minimal inspection required, because Senga has an excellent in-house quality assurance system and proven track record of exceptional quality, thus eliminating the time and cost of incoming receiving inspection on our end.”

President, Major Alternative Energy Industry Manufacturer

Professionalism & turnaround time have been exceptional

“I feel privileged to have Senga Engineering with their capacity and capabilities. Their professionalism and turnaround time have been exceptional, not to mention the excellent care & dedication that Mike Irion shows every day. Always willing to go the extra mile to get us what we need.”

Business Operations Manager, Fiber Optic Interconnect Solutions Provider

Industries & Applications

Industrial

Full-service machine-to-print from billet, castings & forging metal additive parts