World-Class CNC Machining for Demanding Applications in Orbit and Beyond

The commercial space race has vastly increased the need for precision CNC components that perform under pressure – or, perhaps more accurately, perform in the absence of pressure.

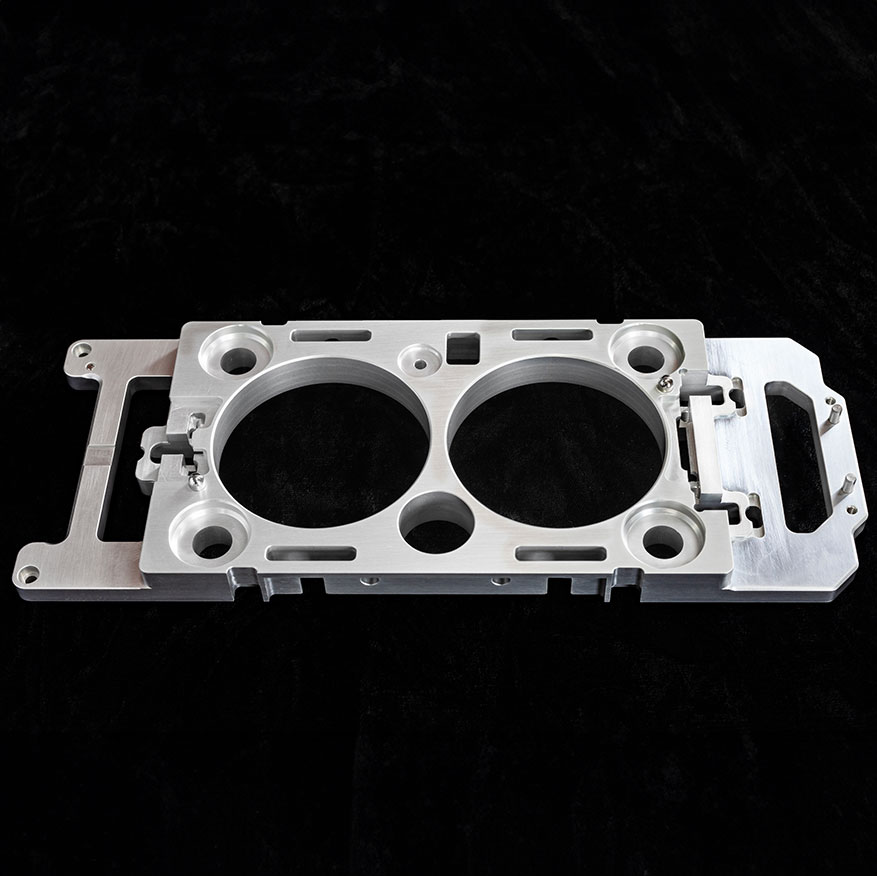

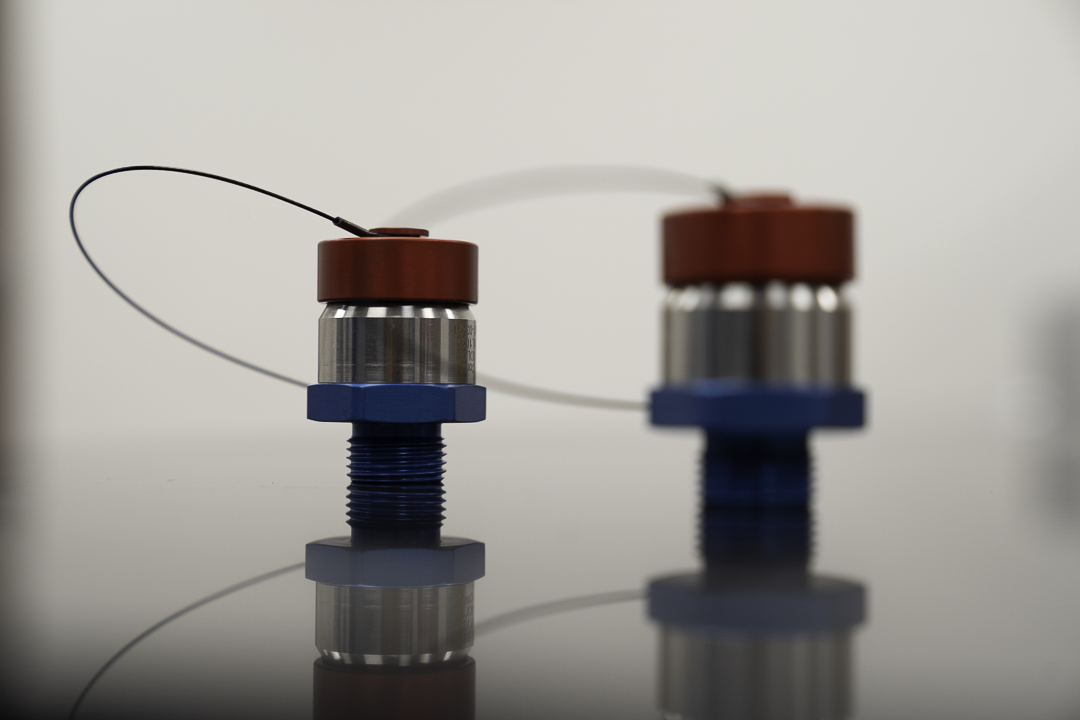

Complex machined parts and subassemblies for space applications typically use exotic materials due to weight considerations, are inert with oxygen and fuels, and able to withstand extremely high and low temperatures.

These parts must meet rigorous standards for quality and accuracy, and engineers need a manufacturing partner who can deliver out-of-this-world results for successful projects.

Senga Engineering is a leading provider of precision CNC components for space applications. Our shop floor can be configured for small-quantity R&D parts that have a pathway to production or large-volume machining without ever sacrificing quality or accuracy.

The Senga team also generates complex components at volume over multi-year production lifecycles by storing qualified machine set-ups and palletized milling for both horizontal and 5-axis work centers.

Full Accountability & Traceability From Dock to Stock

- Proven quality creates significant savings by eliminating the need for receiving inspections

- Serialization and robust documentation provide detailed lot traceability

- We are ITAR-controlled, ISO:9001, AS9100:D, and federally licensed for firearms components production

- Since our inception in 1979, we have been veteran-owned and privately held

The Senga Difference

CNC Machining Capabilities

40+ state-of-the-art CNC machine tools for minimal handling and unmatched quality.

Multitask Machining

Get the highest accuracy for complex applications with lathe, vertical, or horizontal machining centers and material handling operations in one setup.

Multi-Axis CNC Turning

Ensure precision with two dozen Okuma lathes capable of .25- to 12.0-inch diameters. Single-operation finishing from bar-fed material also reduces handling.

Multi-Axis CNC Milling

Choose high-efficiency continuous production from 3- to 11-axis CNC milling and turning machines that ensure accuracy for the most complex components.

Turnkey Manufacturing Solutions

Automation

Uplevel your parts with finishing, marking, heating, assembly, pre-production engineering services, and more through Senga’s supply chain.

Additive Manufacturing (3D Printing)

Increase productivity and profitability with rapid prototyping to full-scale production runs using premium materials to reduce costs and lead times.

Swiss Turning Support

Secure the smallest precision components with the tightest tolerances machined from the best materials for the most essential applications.

Frequently Asked Questions

What materials do you machine? Are you capable of machining exotic alloys like inconel and titanium?

Is your company AS9100:D registered? Do you offer First Article Inspection per AS9102?

Do you machine castings and forgings?

Is Senga willing to establish LTAs and/or Blanket Orders? Are you willing to stock parts for us?

Are you capable of performing 100% inspections and serializing parts?

Design for Manufacturability eBook

Find out exactly how to create designs that are practical and optimized for the manufacturing process