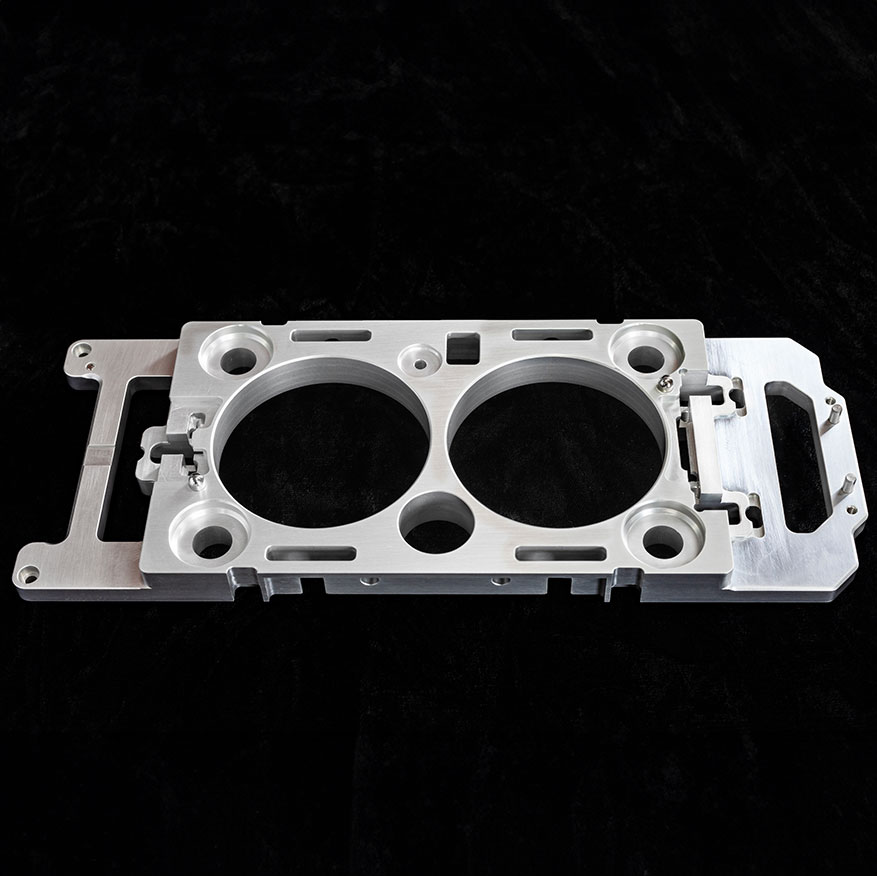

3D Printing & Additive Manufacturing Capabilities

Lightweight & robust parts at a lower cost than traditional CNC machining

Increased Productivity & Profitability From Unique Components

Additive non-metal manufacturing, commonly known as 3D-printing, can produce prototypes and low-quantity parts at a lower price than traditional manufacturing methods.

Compared to CNC machining, 3D-printed parts take less time to produce, require less setup, and generate virtually no scrap material. Also, the cost remains the same no matter how complex the design.

Senga’s engineers incorporate FFF/FDM additive manufacturing technology to produce parts that are lightweight, robust, and available more quickly than projects that require precision CNC machining.

Make it right the first time with state-of-the-art 3D-printing and quality assurance from Senga.

- ABS-ESD7 prevents static build-up, making it ideal for use in electronics and fixturing for electronic components

- ABS-M30 is an easy-to-use polymer that delivers rapid prototypes for form, fit, function, and fixturing

- ABS-M30i is biocompatible, offering the same ease of use and rapid prototyping as ABS-M30 to the fields of medical and food packaging

- Antero 800na is capable of withstanding exposure to hydrocarbons and heat, making it a great candidate for prototyping and production runs of components

- ASA offers a wide array of colors and finishes for modeling and fixturing, as well as the greatest strength and resolution of the plastics

- Nylon 12 and Nylon 6 resist the wear and tear of repeated use, making them optimal for parts that face repeated wear or require a snap-fit

- Nylon 12 Carbon Fiber provides a high-strength option capable of replacing some metal tooling and offers production-level quality parts. Nylon 12 Carbon Fiber’s strength is comparable to 6061-T6 Aluminum with lighter weight and no required tooling

- Polycarbonates are best used in modeling and tooling and are ideal for automotive and aerospace applications

- Polycarbonate ABS offers the same heat resistance and strength as standard polycarbonate with a wider range of uses. ABS and ASA polymers are optimal for prototyping, tooling, and low-volume manufacturing

- Polycarbonate ISO is a heat-resistant, bio-compatible, FDA-approved thermoplastic ideal for use in the medical, pharmaceutical, and food packing industries

- Ultem 9085 is an aerospace-grade resin with high heat, chemical, and FST tolerances used in the aerospace and automotive industries

- Ultem 1010 is a bio-compatible variation of the Ultem resin that retains the 9085’s heat and chemical resistance

- SR-130, SR-30, and SR-35 are specifically designed as dissolvable supports for use throughout the additive manufacturing capabilities of the Fortus 450mc

Proven track record of exceptional quality

“Senga delivers high quality complex parts that go from our dock to our production floor with only very minimal inspection required, because Senga has an excellent in-house quality assurance system and proven track record of exceptional quality, thus eliminating the time and cost of incoming receiving inspection on our end.”

President, Major Alternative Energy Industry Manufacturer

Professionalism & turnaround time have been exceptional

“I feel privileged to have Senga Engineering with their capacity and capabilities. Their professionalism and turnaround time have been exceptional, not to mention the excellent care & dedication that Mike Irion shows every day. Always willing to go the extra mile to get us what we need.”

Business Operations Manager, Fiber Optic Interconnect Solutions Provider

Industries & Applications

Industrial

Full-service machine-to-print from billet, castings & forging metal additive parts