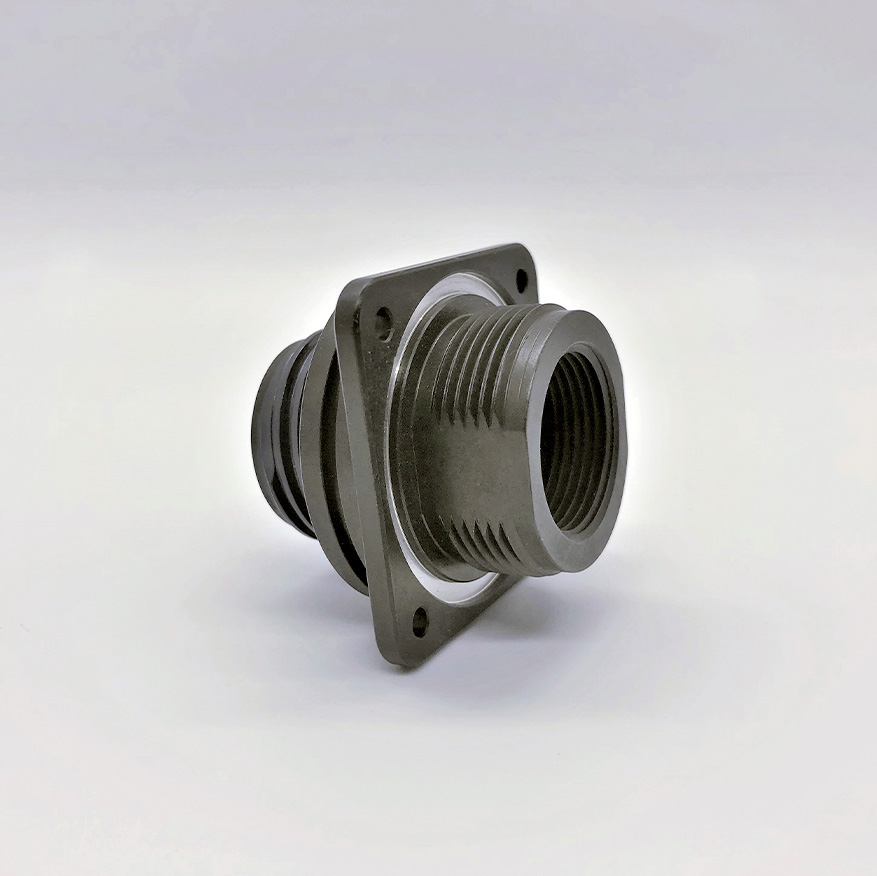

Automated Solutions for Unmatched Accuracy in Precision CNC Machining

State-of-the-art automation tools & industry expertise combine to produce repeatable and precision CNC solutions that meet the highest standards.

Embracing Innovations to Deliver Manufacturing Excellence

Meeting customer expectations for complex parts that work in demanding applications requires continual investment in the latest precision CNC machining technologies.

As an industry leader in advanced precision CNC machining solutions, Senga Engineering leverages cutting-edge systems that use automation and machine learning to optimize production runs, reduce turnaround times, and maintain the highest levels of quality.

Make it right the first time with modern automation, precision CNC machining, and quality assurance from Senga.

Senga’s 24-pallet Mori Seiki Linear Pallet Pool (LPP) system reduces setup and inspection time and ensures the highest level of machining accuracy.

- It is connected to two NH4000 machines, each of which is equipped with a 240-station tool changer

- The flexible multi-layer pallet pool system can handle up to three different pallet sizes

- Options for monitoring and tool management across all relevant areas are included

In addition to these features, the LPP system also stores multiple setups for faster, more efficient production.

Our palletized 5-axis mills allow for large production volumes through state-of-the-art technology and machinery.

- These cells enable unattended and uninterrupted machining for any large production orders

- Manual tool changes are unnecessary

As used by our experienced team, vertical, palletized manufacturing reduces the need for multiple setups, handling, and inspections that slow production and increase costs.

Our team uses a number of CAD/CAM tools to collaborate with engineers on a design level, maximize manufacturability strategies, and share information for process improvement. Tools we use include:

- Solidworks for designing tooling and fixturing

- PC-DMIS CMM for creating and executing CMM measurement routines on the shop floor

- Esprit, the most powerful CNC programming software available, allows us to optimize programs for the shortest cycle times possible while maintaining quality, finish, and precision

Leading-edge tools and processes ensure that our clients can be confident in the quality and accuracy of every production run, no matter how complex.

Proven track record of exceptional quality

“Senga delivers high quality complex parts that go from our dock to our production floor with only very minimal inspection required, because Senga has an excellent in-house quality assurance system and proven track record of exceptional quality, thus eliminating the time and cost of incoming receiving inspection on our end.”

President, Major Alternative Energy Industry Manufacturer

Professionalism & turnaround time have been exceptional

“I feel privileged to have Senga Engineering with their capacity and capabilities. Their professionalism and turnaround time have been exceptional, not to mention the excellent care & dedication that Mike Irion shows every day. Always willing to go the extra mile to get us what we need.”

Business Operations Manager, Fiber Optic Interconnect Solutions Provider

Industries & Applications

Industrial

Full-service machine-to-print from billet, castings & forging metal additive parts