Why Senga?

Effortless customer experiences through consistent, reliable, and accurate precision CNC machining.

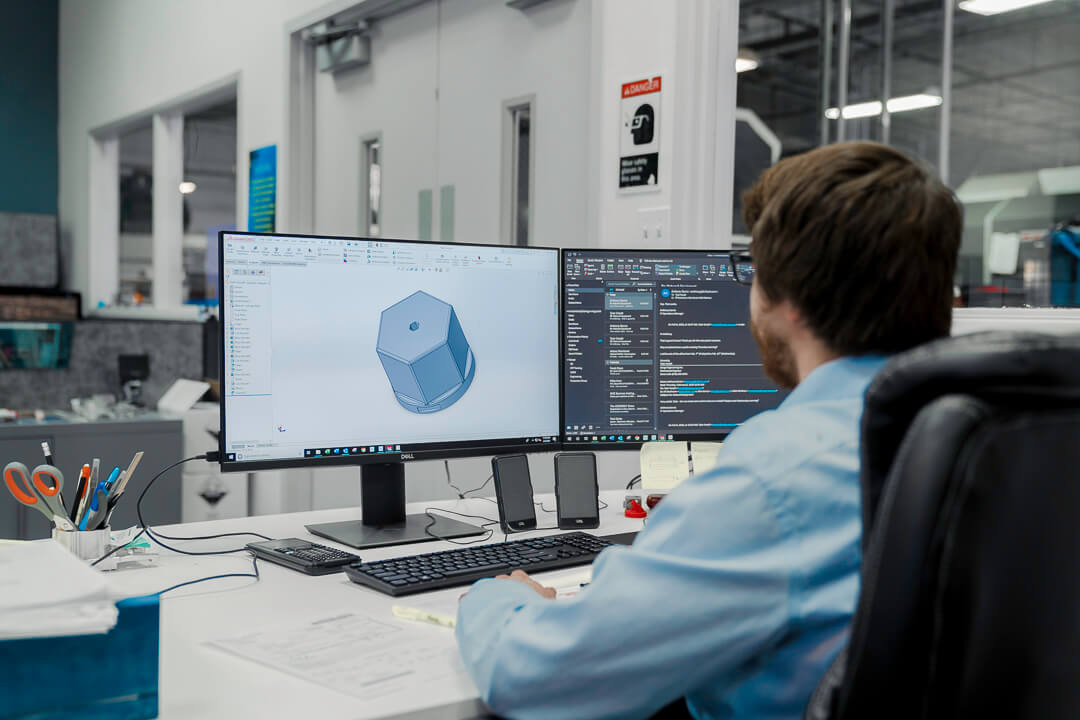

About Senga Engineering

Senga Engineering is a privately held, veteran-owned precision CNC manufacturer in Santa Ana, California.

Founded as a machine shop in 1979, today Senga is a leading provider of complex machine components, subassemblies, and turnkey solutions for applications in critical industries.

Through a dedication to strategic growth that includes a 14% annual capital reinvestment in cutting-edge technology and holistic supply chain development, we have built a reputation for consistently satisfying customers’ quality and scheduling requirements.

Senga’s on-the-floor CMM inspections and “dock-to-stock” capabilities give us the ability to produce complex parts from a variety of materials with fewer operational steps and less handling. These processes make production cycles highly efficient for the most demanding CNC manufacturing needs.

Certifications

AS9100 is the international Quality Management System standard for the Aviation, Space and Defense (AS&D) industry, created by the IAQG, and AS9100 Rev D (2016) is the most recent version. The standard provides suppliers with requirements for creating and maintaining a comprehensive quality system for providing safe and reliable products to the ASD industry, as well as civil & military aviation requirements. “AS9100 Certified” means an organization has met the requirements of AS9100D.

INTERNATIONAL TRAFFIC IN ARMS REGULATIONS

Senga must control all customer drawings designated as “Under ITAR Control” to prevent escape of technical data out of Senga engineering by all means including electronic data. Senga is required to control all parts produced that are subject to ITAR Controls. This includes accounting for all parts produced including all scrap. All Management staff needs to be trained for the management of ITAR Controlled Product and Technical Data. All Production staff must be trained for processes and procedures that are under ITAR control. This includes Senga’s ITAR Control Procedure QOP 87-01 “ ITAR Control”

The Federal Firearms License (FFL) allows individuals to engage in business related to the manufacture of ammunition or firearms or the interstate or intrastate sale of firearms. Holding an FFL to pursue these activities has been a legal requirement in the United States since 1968, with the passage of the Gun Control Act. It is administered by the U.S. Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF), which is housed within the U.S. Department of Justice.

From Blueprint to Delivery:

The Senga Engineering Process

Ensure the best value and quality for your components

1

Project Review

- Submit your drawing and Request for Quote (RFQ) to start the process.

- Senga will analyze and develop the bill of materials and plans for manufacturing and inspection, including design for manufacturability support. Quality Assurance begins with manufacturing and process design.

- Your completed electronic quote will include:

- Your proposed part number

- Revision level

- Quantity price breaks upon request

- Any outside services required

Manufacturing

- After agreeing on a project plan, your Senga team will procure materials and organize multi-axis CNC setups for a thorough first-article inspection and approval before production.

- Critical in-process inspections are built into production and assure conformity to print using:

- Surface profilometers

- Vision systems

- Shop-floor measuring machines

- Bluetooth enabled handheld gauges for seamless, flawless data collection

Finalize Shipment

- Senga verifies on-time order deliveries during production

- Each component is finalized with value-add services that include:

- Finishing

- Marking

- Heat-Treating

- The kitting department completes:

- Assemblies

- Kitting

- Special Packaging (Totes)

- To verify quality via thorough assessments and inspections, parts are delivered with:

- A Certificate of Conformance

- Inspection reports

- Material certs

- Processing certs

Core Values

The Senga team is passionate about the success of our customers, employees, and community. We live out our dedication to each of these groups through our Core Values.

We Add Value

Consistently evaluating our processes ensures maximum value for our customers and minimizes wasted resources

We Embrace Challenges

Difficult parameters, extreme precision, and leading-edge components are solvable opportunities, not obstacles

We Support Personal Growth

Thriving employees help Senga meet objectives for product quality, on-time delivery, and manufacturing excellence

We Communicate & Trust

Open dialog and collaboration are essential for everything from manufacturability in design to delivery schedules

We Are Authentic

Conversations with the Senga team are always candid and straightforward to ensure clarity and production success

Meet the Team

Senga’s long-tenured team brings decades of institutional experience and practical expertise to every precision CNC manufacturing project. Get to know the folks you’ll be working with here.

See What Success with Senga Looks Like

Hear From Our Partners

Proven track record of exceptional quality

“Senga delivers high quality complex parts that go from our dock to our production floor with only very minimal inspection required, because Senga has an excellent in-house quality assurance system and proven track record of exceptional quality, thus eliminating the time and cost of incoming receiving inspection on our end.”

President, Major Alternative Energy Industry Manufacturer

Professionalism & turnaround time have been exceptional

“I feel privileged to have Senga Engineering with their capacity and capabilities. Their professionalism and turnaround time have been exceptional, not to mention the excellent care & dedication that Mike Irion shows every day. Always willing to go the extra mile to get us what we need.”

Business Operations Manager, Fiber Optic Interconnect Solutions Provider

Opportunities at Senga

Joining the Senga team means collaborating with dedicated professionals who have a passion for new technology. Learn more about pursuing a career that fulfills your potential as part of a passionate and tech-savvy team.